Sheet Metal Fabrication

Our advanced metal working capabilities enable us to cut and form sheet metal into intricate shapes and complex components.

We specialize in difficult to manufacture parts and assemblies, with extremely close tolerance features and finishes:

Laser Cutting

We have been laser cutting parts since 1996

Laser cutting is an extremely versatile and cost effective process for producing flat pattern blanks. Burr free parts with superior edge quality can be cut from virtually any type of material, without exception to extreme contours or close tolerances.

Our laser cutting systems allow us to cut materials up to 5/8” thick. We also have the flexibility in our cutting operations to process everything from unlimited length coil stock to prefabricated components.

The real advantages of laser cutting are the elimination of hard tooling and the ability to closely nest parts for maximum material utilization. All of this leads to ultra fast turnaround times for prototypes or production and a reduction in the overall cost of producing parts……….critical in today’s just-in-time and competitive environment.

CNC Turret Punching

The CNC turret punch press is a high speed and cost effective method for producing sheet metal parts in moderate to high volumes. The process is ideal for punching parts with large quantities of perforated holes or multiple features. Close tolerances can be held with remarkable throughput.

By utilizing the latest software and modern tooling innovations, we can produce parts to exacting dimensions in a variety of shapes, including offset bends, extrusions, ribs, embosses or many other shaped or formed features.

AAFI also maintains a vast library of punch tooling, which means we can be tooled up and ready to produce our customer’s parts extremely fast.

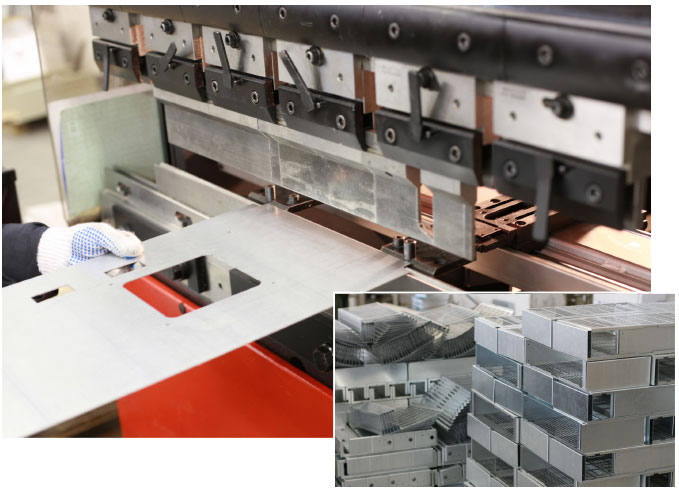

CNC Forming

AAFI operates a wide range of equipment for producing multitudes of parts in various shapes and sizes. Our press brake department is capable of forming precision, complex parts with multiple bends and compound angles…..all in one set-up.

Our CNC servo electric press brakes are equipped with 6-axis gauging and automatic sheet thickness sensing. Our master press brake technicians use these machines to produce parts with the highest degree of accuracy and repeatability.

For larger parts we use hydraulic machines with multi-axis CNC gauging and forming capabilities up to 125 tons by 10ft long.

Laser/Turret Punch Combo

This versatile machine provides the ultimate process for producing sheet metal parts by incorporating seamless integration of punching and laser function. Additionally, it includes tapping tools and die lift stations for threading and forming right in the machine. With punching speeds of up to 370 HPM and the combined cutting efficiency of a 2500 watt laser, this flexible machine tool gives AAFI the ability to fast-track projects.

Adding this equipment to our arsenal of capabilities reflects our ongoing commitment of providing our customers with quick responses and increased productivity.