Welding

Our welders specialize in close tolerance welded assemblies and are equipped to handle a full range of materials using multiple processes:

TIG Welding

Precision Gas Tungsten Arc Welding (GTAW) is one of our specialties. This process grants the operator greater control over the weld allowing for stronger, higher quality welds. We have multiple TIG welding stations and all of our welding technicians have mastered this process.

MIG Welding

Some manufacturing projects are better suited for the Metal Inert Gas (MIG) welding process….or even in combination with the TIG process. AAFI has many years of experience in this process and our expertise covers the welding of carbon steel, stainless steel, aluminum and more.

Spot/Projection Welding

AAFI also offers resistance spot welding as part of our production services. This process is typically used when the weld joint design calls for sheet metal to be laminated. Projection welding is also used to install certain types of weld-in-hardware. All of our machines are outfitted with solid state microprocessors for accurate control of all weld parameters.

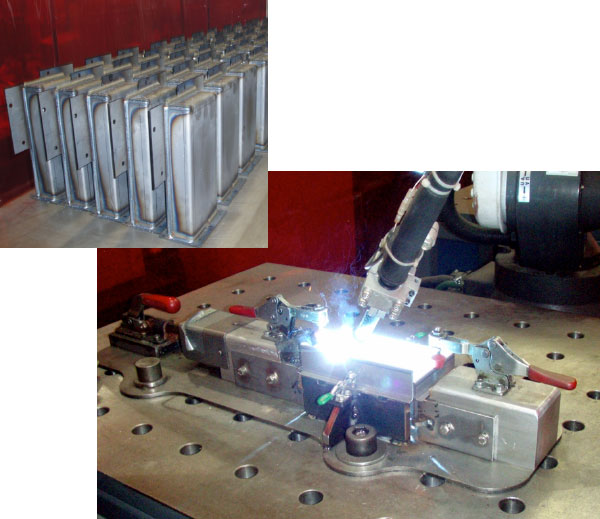

Robotic MIG Welding

In order to maximize our welding throughput on certain projects, AAFI operates a six axis robotic welding cell. This welding robot enables us to produce complex welded assemblies while shortening manufacturing lead times.

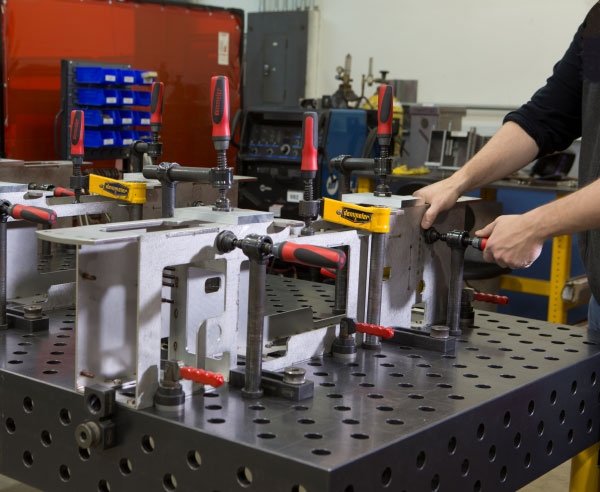

Modular Fixturing

Every weld station in the AAFI welding department is outfitted with a modular fixturing table. We currently have over a dozen of these tables in use, including sizes up to 1200 mm x 2400 mm (4’ x 8’). This precise, flexible and repeatable 3D clamping system gives us the ability to accurately position and fasten components together for welding. For most projects, modular fixturing has eliminated the need for dedicated welding fixtures which are time consuming and expensive to build. Our initial set-up times have been reduced and the transition from prototype to production is seamless and fast.